Quality

THE LABORATORY IS EQUIPPED WITH:

- FARO measuring arm

- universal testing machine - ZWICK Z100 ProLine

- impact hammer - ZWICK type RKP 450 GE

- Brinell hardness tester - ZWICK ZHB 3000; BOSS OS-300WE-7 reading optics

- device for ultrasound testing KARL DEUTSCH Echometer 1077/6 and 1075

- SPECTROLAB spectrometer

- microscope

- MINCO-ROTOCAST melting furnace

- digital measuring equipment

- device for testing the properties of molding sands

- Leco carbon and sulfur analyzer

- paint coating thickness gauge

- ITACA thermal analysis system.

WE MAKE ON CUSTOMER'S REQUEST:

- X-ray examinations (in accordance with PN-EN 12681: 2005)

- magnetic tests (in accordance with PN-EN 1369).

The high quality of produced castings, as well as the quick launch of new items in line with the expectations of customers, is ensured by modern production technology and experienced international engineering and technical staff working on the programs:

- Solid Edge ST9 (CAD)

- Novaflow & Solid (simulations).

SPECTRAL ANALYSIS

Is one of two methods that was used to determine the chemical composition of liquid metal. Each individual melt is tested for compliance of the chemical composition with the specified specifications.

THERMAL ANALYSIS

Is the second method we use to determine the chemical composition of liquid metal. Thanks to its speed in determining metallurgical parameters, we are able to detect and correct nonconformities faster. Every change in the metallurgical quality of metal is monitored on an ongoing basis by the ITACA 8 system.

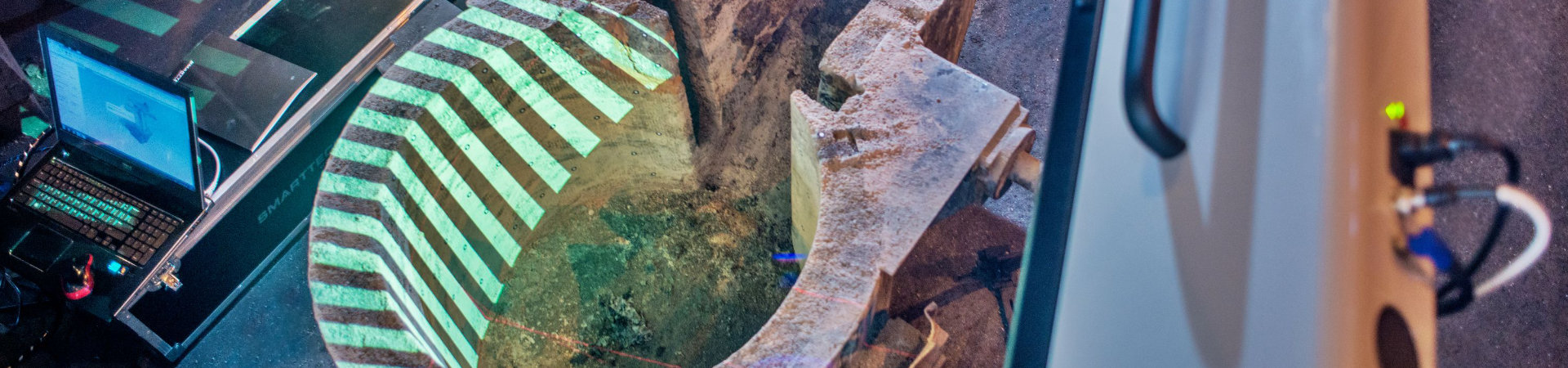

DIMENSIONAL CONTROL

In the Measuring Laboratory, the castings are checked whether the dimensions are in accordance with the dimensions provided by the customer. The laboratory is equipped with digital measuring equipment and the FARO measuring arm

CONTROL OF MECHANICAL PROPERTIES

In the endurance laboratory we examine whether the mechanical properties of castings are in accordance with the customer's specification. Controlled properties are:

- Tensile strength Rm

- Yield point Rp0,2

- A% elongation

- HB hardness

- Impact strength KV

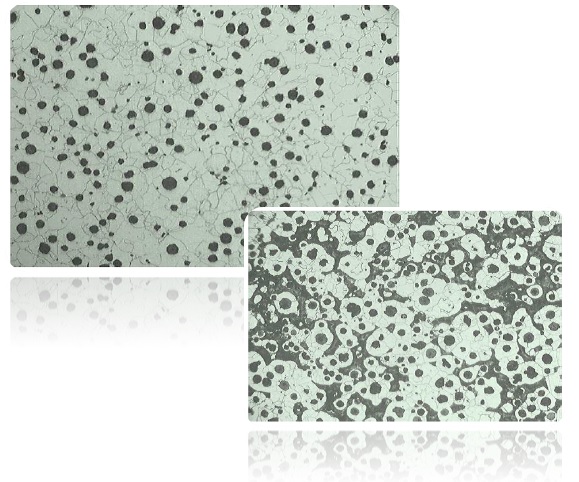

MICROSTRUCTURE ANALYSIS

In the metallographic laboratory, we perform a microstructure analysis of cast samples to determine such things as:

- The shape of graphite

- Distribution

- Size

- Proportions of ferrite and perlite

- Carbide content

- Graphite spheroidality

TESTING OF PROPERTIES OF MOLDING MASSES

During each production change, molding sand samples are sent to the laboratory to analyze parameters such as:

- Percentage of water

- Tensile strength

- Compressive strength

- Shear strength

- Permeability

- Compactibility

- Tensile strength in the condensation zone

- Roasting losses

- Active clay content